How to Control Alcohol Levels in Commercial Kombucha Production

Your QA manager just tested yesterday's batch. 0.6% ABV. You're over the limit.

Now you're facing a choice: dump the batch, pasteurise it and kill the live culture positioning your brand is built on, or risk shipping it and hoping nobody tests it. None of these options feel good.

For commercial kombucha producers, alcohol control isn't a quality issue. It's a regulatory minefield. If your kombucha reaches 0.5% ABV in most markets, it shifts from soft drink to alcoholic beverage classification. That means alcohol licensing, formula approvals, excise taxes, and distribution restrictions that can derail your business model entirely.

The brands successfully scaling kombucha aren't getting lucky with low alcohol levels. They've built systems that keep ABV predictably below regulatory thresholds, batch after batch. This post walks through why kombucha alcohol is so unpredictable, what the regulatory landscape actually looks like, and the methods proven to deliver consistent compliance.

Download our free Kombucha Troubleshooting Guide for practical solutions to alcohol control, batch consistency, and the production challenges that hold brands back from scaling efficiently.

Why Kombucha Alcohol Is So Unpredictable

Traditional kombucha fermentation is a biological balancing act. Yeast consume sugar and produce alcohol. Bacteria (acetobacter) convert that alcohol into acetic acid. When this symbiosis stays balanced, alcohol levels remain low. When it tips towards yeast dominance, alcohol spikes unpredictably.

Temperature fluctuations accelerate yeast activity. Warmer temperatures (anything above 26°C) favour alcohol-producing yeasts over acetobacter. Even a 3-4°C swing between day and night can push batches over the limit. Most small-scale facilities don't have climate-controlled fermentation rooms. You're at the mercy of seasonal shifts, HVAC reliability, and whether someone left a door open.

Secondary fermentation in bottles continues after packaging. You bottle at 0.3% ABV, which feels safe. Two weeks later, that same bottle tests at 0.7% because residual sugar kept fermenting. Regulators don't care that it was compliant when you sealed it. If it ever hits the threshold, you're facing reclassification.

SCOBY health and yeast balance drift over time. A culture that's been running for months without refresh can shift towards yeast dominance, producing more alcohol than bacteria can metabolise. You don't always see it coming. One week your batches are fine. The next, every tank is creeping towards 0.5%.

The result? Batch-to-batch alcohol levels that feel random, stressed QA teams testing every tank twice, and constant worry about compliance audits. It's expensive. It's exhausting. And it doesn't have to be this way.

Know Your Regional Alcohol Thresholds

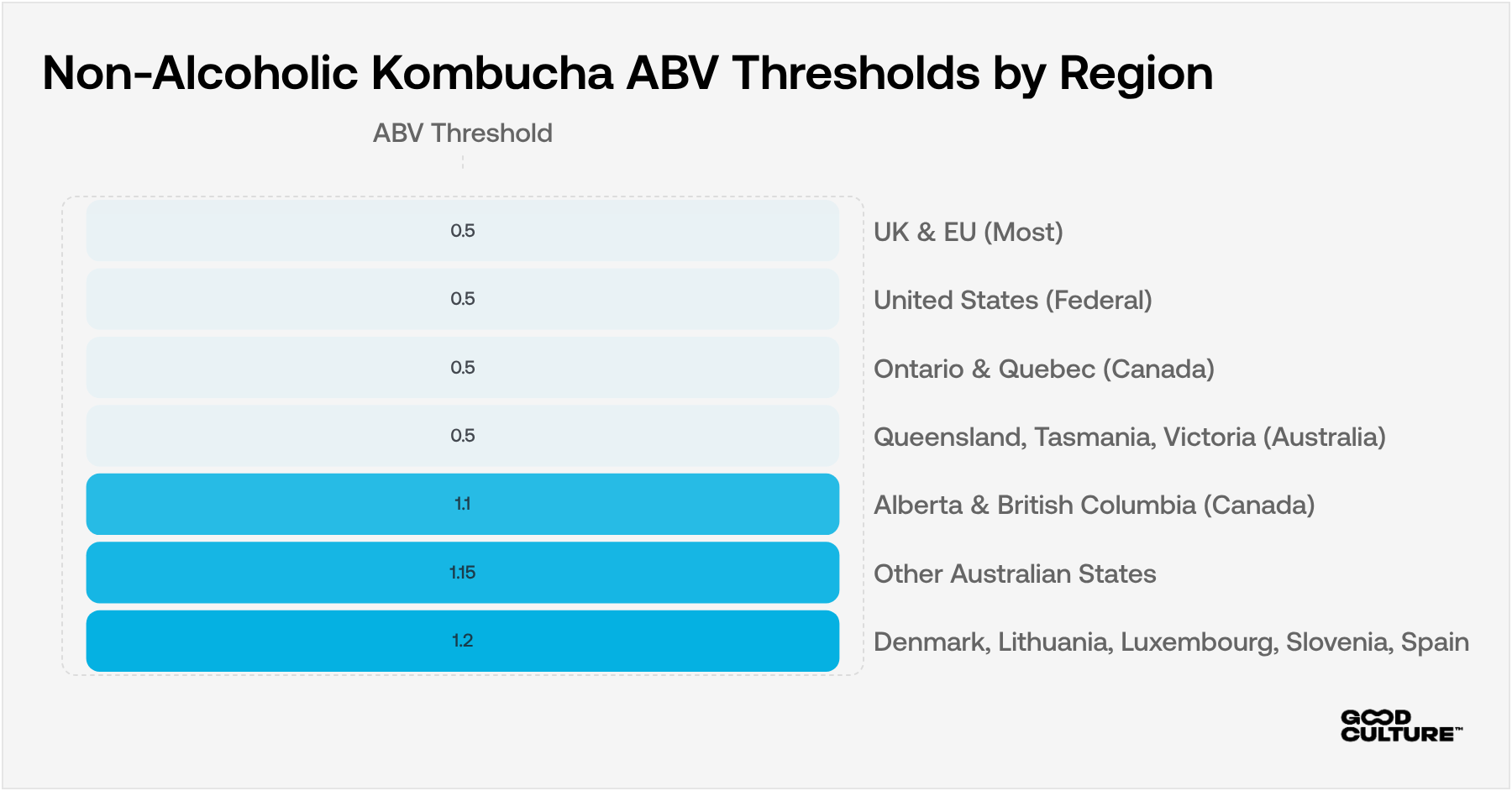

Regulatory thresholds for "non-alcoholic" kombucha vary significantly by jurisdiction. If you're distributing across multiple regions, understanding these differences isn't optional.

Most of the UK and EU enforce a 0.5% ABV threshold. Above this, you need alcohol licensing. Some EU member states (Denmark, Lithuania, Luxembourg, Slovenia, and Spain) allow up to 1.2% ABV before reclassification.

Australia varies by state. Queensland, Tasmania, and Victoria require kombucha to stay below 0.5% ABV. Other states allow up to 1.15%. Canada also varies by province. Ontario and Quebec enforce 0.5%, whilst Alberta and British Columbia allow 1.1%. The United States uses a federal 0.5% ABV threshold, requiring TTB registration above this level.

The practical reality? If you're distributing internationally or across multiple regions, target 0.5% ABV. It simplifies compliance, ensures your product qualifies as non-alcoholic everywhere you sell it, and removes the risk of reclassification when entering new markets.

Temperature Control: The Foundation of Alcohol Management

Yeast thrive in warm temperatures. Above 24-26°C, yeast activity accelerates dramatically. They consume sugar faster and produce more alcohol before bacteria can convert it to acetic acid. This is the single most common cause of alcohol spikes in commercial kombucha production.

Maintaining fermentation between 20-24°C is the baseline. This range is cool enough to slow yeast activity whilst allowing bacteria to stay active and metabolise alcohol efficiently. Some producers targeting ultra-low alcohol go even cooler (18-20°C), accepting slower fermentation times in exchange for tighter alcohol control.

The challenge is consistency. Installing temperature-controlled fermentation chambers or glycol-jacketed tanks isn't cheap, but it's the difference between predictable results and constant firefighting. Continuous monitoring with alerts when temps drift outside target range gives you early warning before alcohol levels spike.

If you're struggling with alcohol control and your fermentation room fluctuates more than 2-3°C daily, temperature is almost certainly your problem.

Give Bacteria Time to Metabolise Alcohol

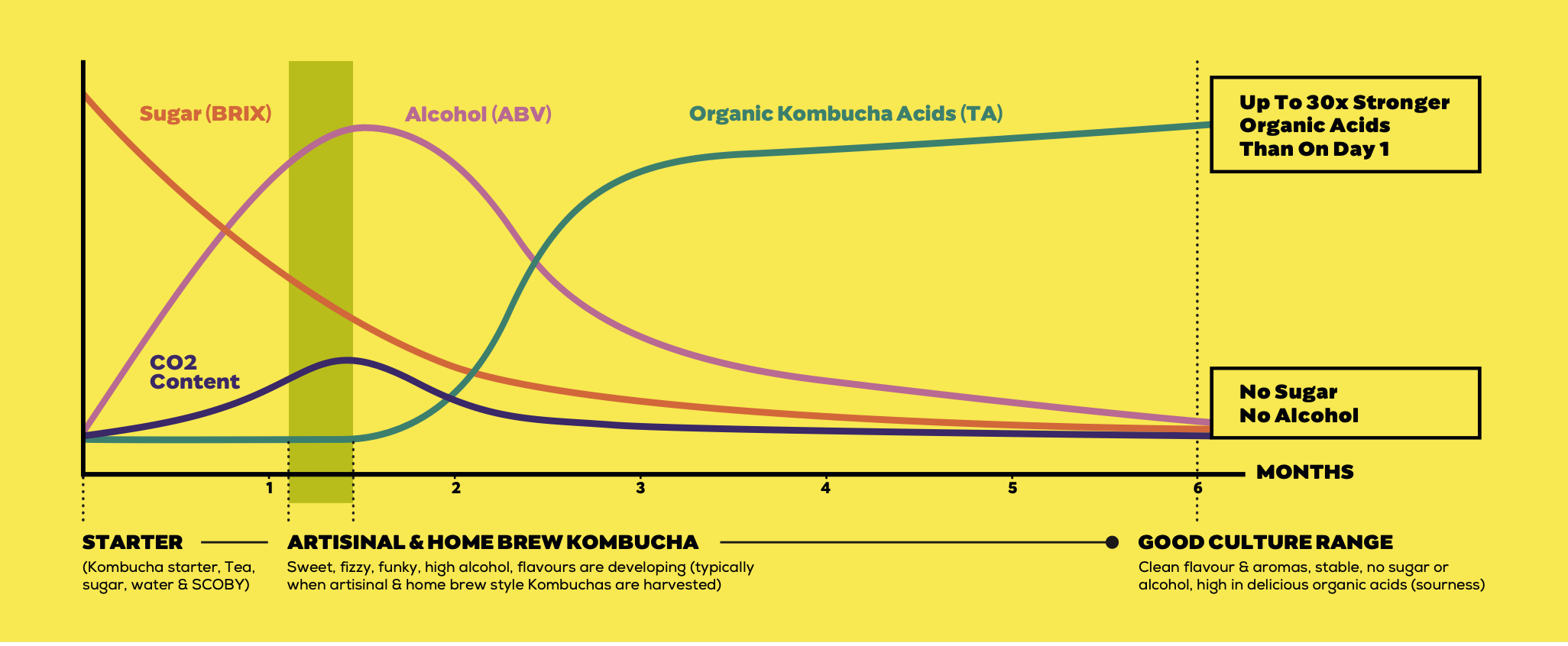

Early in fermentation, yeast dominate. They consume sugar rapidly and produce alcohol. Bacteria take longer to ramp up activity. If you bottle too early, yeast may have produced significant alcohol that bacteria haven't yet metabolised.

Extending primary fermentation to 3 - 6 months instead of 30 days gives bacteria more time to convert alcohol into acetic acid, but of course this takes some time to produce good results. Your kombucha will be tangier, more vinegar-forward. Some brands embrace this. Others compensate by blending long-fermented base with fresh tea or juice during flavouring, or using non-fermentable sweeteners like stevia, erythritol, or monk fruit to add back sweetness without feeding yeast.

The key is testing throughout fermentation to understand your curve. Measure ABV at days 3, 5, 7, and 10. You'll see alcohol rise early as yeast work, then plateau or decline as bacteria metabolise it. That plateau point is your harvest window. Bottle too early, and alcohol keeps climbing in the bottle. Wait for bacteria to catch up, and you maintain control.

Reduce Fermentable Sugar to Limit Alcohol Potential

More sugar equals more potential alcohol. If you're starting fermentation with 60-80g sugar per litre, yeast have plenty of fuel to produce alcohol. Lowering your initial sugar concentration to 40-50g/L gives yeast less to work with.

The challenge is that less sugar equals slower fermentation and less pronounced flavour development. Finished kombucha may taste thin or lack body. You'll need to add non-fermentable sweeteners post-fermentation to hit consumer taste expectations.

This approach works best when combined with other methods. Reducing sugar alone won't solve alcohol issues if your temperature control is inconsistent or your SCOBY balance has drifted. But as part of a broader system, it gives you more control over how much alcohol yeast can produce in the first place.

Manage SCOBY Health and Yeast Balance

Over time, SCOBY cultures can shift towards yeast dominance. If you've been running the same culture for months without refreshing it, yeast populations may have grown disproportionately. The result is higher alcohol production and less bacterial activity to metabolise it.

Rotating or refreshing your SCOBY culture every 2-3 months helps maintain balance. For high-volume operations, this might mean working with commercial SCOBY suppliers who cultivate low-alcohol strains. Some producers periodically harvest excess yeast from the bottom of fermenters to prevent yeast from overwhelming bacteria.

If SCOBY management feels like constant firefighting (refreshing cultures, adjusting ratios, testing balance), consider whether the variability is costing more than it's worth. Ready-to-blend fermented bases eliminate SCOBY drift entirely. You're working with a stable, pre-fermented product that delivers consistent alcohol levels without ongoing microbial management.

Control Post-Bottling Fermentation

You bottle at 0.3% ABV. It feels safe. But residual sugar and live yeast in the bottle continue fermenting during distribution and storage. Three weeks later, a retailer tests that same bottle at 0.6%. You're non-compliant, even though you did everything right during production.

This is one of the most frustrating compliance issues kombucha producers face. The solution requires removing either the sugar or the yeast before bottling.

Fermenting to near-zero sugar during primary fermentation means there's nothing left for yeast to consume in the bottle. Test with a hydrometer or refractometer to confirm sugar is fully consumed before bottling. Add non-fermentable sweeteners and force-carbonate if needed.

Microfiltration removes yeast cells before bottling. Passing kombucha through 0.5-micron filters eliminates yeast whilst preserving bacteria and flavour compounds. The result is a stable product that won't continue fermenting in the bottle.

Pasteurisation uses brief heat treatment to kill yeast and bacteria, halting fermentation entirely. The trade-off? You lose the "live culture" positioning that many kombucha brands are built on.

Many commercial producers combine approaches: ferment to very low sugar, microfilter to remove yeast, then add non-fermentable sweeteners and force-carbonate. The result? Stable, predictable alcohol levels that stay well below thresholds indefinitely.

Test Relentlessly and Document Everything

You can't manage what you don't measure. If you're only testing finished product occasionally, you have no idea where in your process alcohol spikes. Testing throughout fermentation gives you visibility into your fermentation curve and helps you identify exactly when alcohol rises and when bacteria metabolise it.

Test during fermentation at days 3, 5, 7, and 10. Test finished product from every batch, every tank, before bottling. Pull bottles from finished batches and test at 2 weeks, 4 weeks, and 8 weeks to understand post-bottling drift.

Use reliable lab-grade testing methods. Gas chromatography and enzymatic assays are accurate to ±0.05%. Handheld metres and homebrew hydrometers can have ±0.1-0.2% error, which is massive when your compliance threshold is 0.5%. Invest in proper lab testing or third-party verification for commercial operations.

Document rigorously. Regulatory audits and retailer compliance checks require proof. A single non-compliant batch caught by regulators or retailers can cost your business far more than proactive testing. Understanding the hidden costs of inconsistent production includes compliance risk. Prevention is exponentially cheaper than dealing with non-compliance fallout.

Download our Kombucha Troubleshooting Guide for proven strategies to stay below regulatory alcohol thresholds and build testing protocols that actually work.

Here’s an outline of how the fermentation process works for our Good Culture range of fermented bases.

When Process Control Reaches Its Limits

Despite best efforts, some commercial operations find traditional fermentation-based alcohol control unsustainable. Variables stack up: seasonal temperature shifts, ingredient batch variations, SCOBY drift, and the inherent unpredictability of live fermentation. When process control reaches its limits, smart producers look at alternative production models.

Pre-fermented kombucha bases are fully fermented, shelf-stable kombucha concentrates that have already completed their volatile fermentation phase. These bases deliver authentic fermented flavour, organic acidity, and stable, predictable alcohol levels. No ongoing microbial activity that creates compliance risk.

You maintain "fermented" positioning. You keep production simple: blend, flavour, carbonate. And you eliminate alcohol uncertainty entirely. Our Organic Green Tea base ensures finished products stay below 0.025% ABV. Our Black Tea base keeps them below 0.04% ABV. That's not cutting corners. That's engineering reliability into your process.

With 40 years of fermentation science behind us and over 1,000 formulations in market, we've helped brands scale kombucha production from sub-500L per month to multi-tonne operations. No traditional compliance burden. Our certified bases meet SQF, Organic, Kosher, and Halal standards, which means they integrate seamlessly into retailer-facing supply chains.

Explore our full range of fermented beverage solutions and see how certified kombucha bases support faster, compliant scaling.

Build Systems That Deliver Compliance Every Time

Kombucha alcohol management isn't about making perfect batches once. It's about building systems that deliver predictable, compliant results every single time. The brands scaling successfully aren't getting lucky. They've eliminated the variables that cause alcohol spikes.

Whether that means tighter process control, microfiltration, pasteurisation, or working with fermented bases that remove alcohol risk entirely, the path forward requires choosing approaches that match your production realities and brand positioning.

If you're hitting roadblocks (inconsistent batches, slow fermentation cycles, or alcohol control issues), start with our Kombucha Troubleshooting Guide. It systematically addresses the most common production challenges holding brands back from scaling efficiently.

Get in touch with our team to see how certified kombucha bases support predictable alcohol control and compliant scaling.

Frequently Asked Questions

-

Most commercial producers target 0.2-0.3% ABV in finished product to provide buffer for post-bottling drift and testing variability. If you're consistently hitting 0.4-0.5%, you're cutting it too close. One batch variation or one warm distribution cycle could push you over. Factor in a margin.

-

Lab-grade methods (gas chromatography, enzymatic assays) are accurate to ±0.05%. Handheld metres and homebrew hydrometers can have ±0.1-0.2% error, which is massive when your compliance threshold is 0.5%. Invest in proper lab testing or third-party verification for any commercial operation.

-

In most jurisdictions, "alcohol-free" claims require less than 0.05% ABV, not 0.5%. Kombucha below 0.5% is classified as "non-alcoholic" (different term, different threshold). Check your local labelling regulations carefully. Mislabelling can trigger regulatory action even if your product is technically compliant.

-

At minimum, your product gets pulled from shelves. At worst, you face penalties, back taxes, and potential legal action for selling alcoholic beverages without proper licensing. Retailers may also refuse future orders and your brand reputation takes a significant hit. Prevention is exponentially cheaper than dealing with non-compliance fallout.

-

It slows fermentation significantly but doesn't stop it entirely. Even at 2-4°C, yeast can slowly metabolise residual sugar and produce alcohol over weeks or months. Cold chain is helpful but not foolproof. The only reliable approaches are eliminating fermentable sugar, removing yeast through filtration, or pasteurising.

-

Yes. Some commercial SCOBY suppliers cultivate cultures with bacterial-dominant profiles and less aggressive yeast strains. However, controlling strain behaviour at commercial scale is challenging because wild yeast from your facility environment can colonise your culture over time. Consistent low alcohol requires process control, not just starter culture selection.

-

Yes. Whilst 0.5% ABV is the most common threshold, some EU member states allow up to 1.2% ABV before alcohol classification applies. If you're distributing across multiple EU countries, target the strictest threshold (0.5%) to ensure compliance everywhere without managing region-specific formulations.