How to Formulate Low-Sugar Kombucha Without Sacrificing Flavour

Your R&D team just finished testing the latest batch of your new low-sugar kombucha.

The nutritional panel looks perfect. 2g sugar per 100ml instead of 8g. Clean label. Exactly what retailers want. There's just one problem. It doesn't taste good.

Too tart. Or maybe it’s too thin. Missing that rounded, satisfying mouthfeel that makes kombucha enjoyable. Your marketing team wanted "guilt-free indulgence." But unfortunately, that's not what they're tasting.

The low-sugar kombucha opportunity is massive. 76% of consumers are actively trying to limit sugar in their diets, whilst 60% want to avoid artificial sweeteners. Brands like Remedy and Health-Ade have built multi-million pound businesses on sugar-reduced formulations. But getting there isn't as simple as fermenting longer or swapping in stevia.

Low-sugar kombucha that actually sells requires balancing taste, texture, shelf stability, as well as clean-label positioning. Here's exactly how to formulate low-sugar kombucha that consumers will buy, retailers will stock, and your brand can scale profitably.

Download our free Kombucha Troubleshooting Guide to learn proven formulation strategies and accelerate your product development.

Why Sugar Reduction Breaks Traditional Kombucha

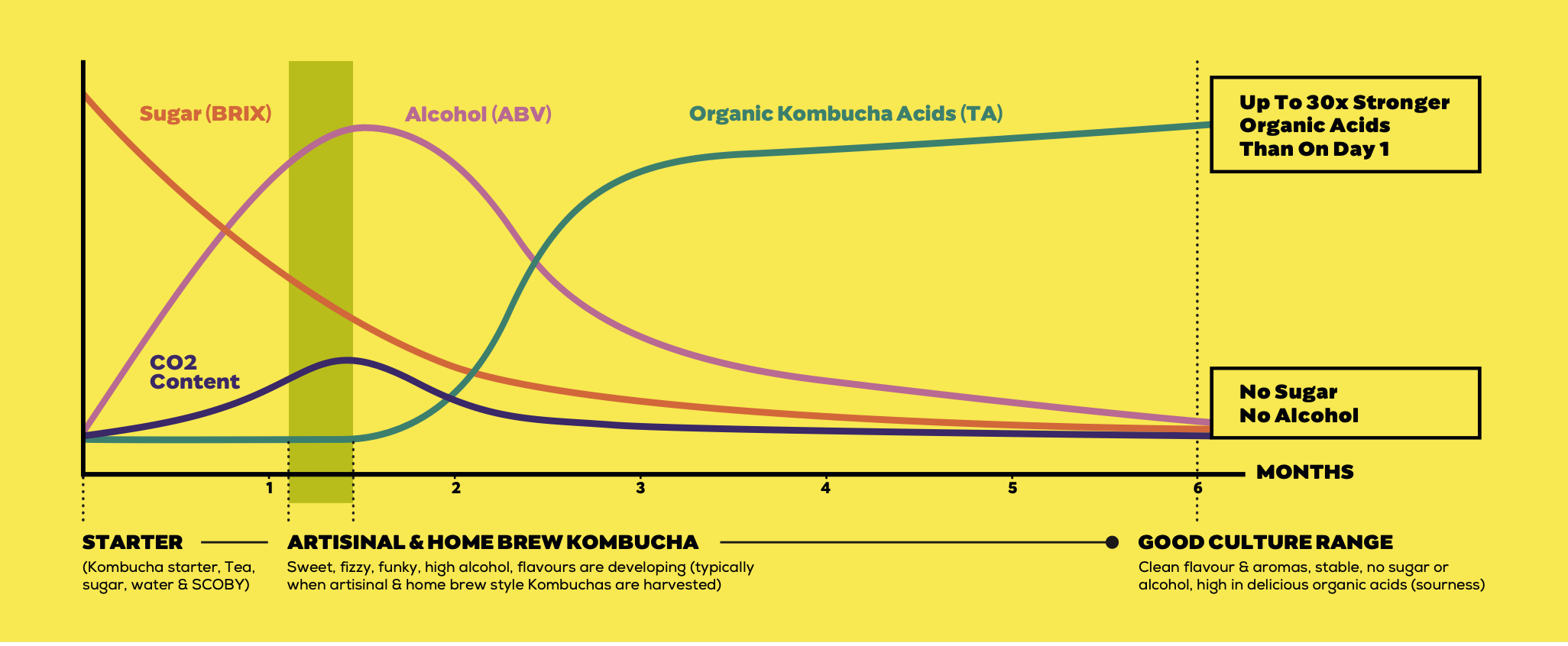

Traditional kombucha starts with 60-80g sugar per litre. During fermentation, yeast and bacteria consume most (but not all) of that sugar, typically leaving 15-40g/L in the finished product. That translates to 4-10g sugar per 250ml serving, putting traditional kombucha roughly in the same league as fruit juice.

For brands targeting health-conscious consumers or mainstream retail placement, those numbers don't work. Retailers increasingly demand products under 5g sugar per 100ml. And consumers expect "healthy" beverages to deliver single-digit sugar counts per serving.

The challenge? Sugar isn't just sweetness in kombucha. It's flavour complexity, mouthfeel, fermentation fuel, and shelf stability. If you remove it carelessly, you lose everything that makes kombucha enjoyable. Less initial sugar means weaker culture health and thinner flavour profiles. Strip out sugar without compensating, and you're left with aggressively sour liquid that most consumers find unpalatable. Sugar contributes body and texture. Low-sugar versions often taste watery and unsatisfying. Getting this right requires methodical formulation work, not guesswork.

Ferment Long, Then Replace Residual Sugar

A straightforward approach? Ferment traditional kombucha to near-complete sugar consumption (3+ months instead of 30 days), then add non-fermentable sweeteners post-fermentation to restore sweetness without reintroducing sugar.

Extended fermentation lets yeast and bacteria consume nearly all initial sugar. Your kombucha finishes at 0-5g/L residual sugar. Very tart, very acidic, but with well-developed fermented character. Then you blend in non-fermentable sweeteners that give you sweetness without feeding microbes.

Erythritol (fermented glucose, naturally occurring in pears and grapes) provides clean sweetness with roughly 70% the sweetness of sugar. Slight cooling sensation. Stevia (plant-based, 300x sweeter than sugar) works at tiny doses (0.2-0.5g/L) but can contribute metallic notes if overused. Monk fruit extract offers clean sweetness without metallic notes but costs significantly more.

Most successful low-sugar kombuchas blend sweeteners (erythritol plus stevia, or monk fruit plus erythritol) to minimise individual off-notes whilst maximising that clean sweetness.

Because fermentable sugars are consumed during primary fermentation, post-bottling fermentation essentially stops. Alcohol levels stay stable, carbonation remains predictable, and shelf life extends significantly (often 6-9 months refrigerated compared to 2-4 months for high-sugar kombucha). Understanding how to control alcohol in commercial production becomes much easier when residual fermentable sugar is minimised.

Use Pre-Fermented Bases for Zero-Sugar Control

The second approach is to skip traditional fermentation entirely. Start with concentrated, pre-fermented kombucha bases that deliver authentic fermented character without residual sugar, alcohol, or fermentation unpredictability. This is how leading low-sugar brands like Remedy and Nexba achieve zero-sugar formulations at scale.

Commercial fermentation specialists produce high-strength fermented tea bases using controlled fermentation, then remove all residual sugar and alcohol. You get shelf-stable concentrate that dilutes 4:1 or 5:1 with water, juice, or tea. Because the base contains zero fermentable sugar from the start, you control sweetness entirely through post-dilution additions of non-fermentable sweeteners.

The production flow is simple. Source concentrated fermented tea base. Dilute to target acidity. Add non-fermentable sweeteners and blend with fruit purées or extracts for flavour. Force-carbonate. Then package it up.

This delivers absolute consistency. Every batch starts from identical fermented base, eliminating the number one source of variability in traditional kombucha production. There’s zero alcohol risk and no SCOBY management. No 3+ month fermentation cycles tying up tank capacity. It means new flavours can go from concept to market in days, not weeks.

Traditional fermentation leaves residual sugar that's hard to control. But pre-fermented bases start at zero sugar, letting you add back exactly the amount you want using non-fermentable sweeteners. You hit target nutritional panels precisely, every single time. Brands using this approach (including major retailers' private label kombucha lines) achieve less than 1g sugar per 100ml and they also maintain authentic fermented tea character.

If these bases are unpasteurised, you also maintain "raw" positioning alongside low-sugar claims. The fermented compounds, organic acids, and authentic kombucha character remain intact without the variability and alcohol risk of traditional fermentation.

Explore Good Culture's fermented beverage solutions, designed specifically for low-sugar kombucha formulation, with technical support to help you achieve target profiles on first production runs.

Build Flavour With Fruit and Botanicals

Another approach starts with lower sugar levels (40-50g/L instead of 60-80g/L) during primary fermentation, then builds flavour complexity through fruit purées, natural extracts, and botanicals during blending.

Lower initial sugar limits alcohol production and reduces residual sugar, but it creates a lighter fermented base. You compensate by layering in natural flavour sources that contribute sweetness perception, mouthfeel, and complexity. Fruit purées (raspberry, mango, passion fruit) add natural sugars, but the fibre and organic acids they contain slow fermentation and contribute mouthfeel. Fresh fruit juices (apple, pear, white grape) contribute natural sweetness with cleaner labelling. Then Botanical extracts (hibiscus, elderflower, ginger) add flavour complexity without contributing calories. But the trade-off is that fruit additions introduce sugars. Although they are natural sugars, your "low sugar" positioning depends on total sugar content remaining below your target threshold (typically less than 5g per 100ml).

Enhance Sweetness Through Acidity Management

Here's another potential move. Manipulate the acid profile of your kombucha to make lower sugar levels taste sweeter than they objectively are. It works because human taste perception is relative. So the same sugar level tastes sweeter in lower-acid environments.

Traditional kombucha fermentation produces primarily acetic acid (vinegary), with smaller amounts of gluconic, lactic, and other organic acids. The balance of these acids dramatically affects taste perception. You can buffer acidity with calcium or magnesium salts. Small additions of food-grade calcium lactate or magnesium citrate round out sharp acidity without a massive rise in your pH. This makes the same sugar level taste sweeter and more balanced.

Blend acids strategically. Adding small amounts of citric acid (bright, clean) or malic acid (soft, round) can mask harsh acetic notes and make kombucha taste more fruit-forward even at lower sugar levels. A kombucha with 3g sugar/100ml and aggressive acetic acid profile tastes thin and sour. The same 3g sugar/100ml with balanced acid profile and subtle calcium buffering tastes rounded, fruity, and satisfying.

Rebuild Mouthfeel Without Sugar

Low-sugar kombucha often tastes thin and flat, even when carbonation levels are correct. Sugar contributes viscosity and body. So when you remove it, beverages feel watery. Here, the fix is to rebuild mouthfeel through non-sugar viscosity enhancers and optimised carbonation.

Pectin (from citrus or apple) can add subtle body without sweetness. Inulin (chicory root fibre, prebiotic) contributes mild sweetness perception and creamy mouthfeel. Guar gum or xanthan gum (at tiny doses, 0.1-0.3g/L) stabilise body without detectable texture.

Higher carbonation levels help mask thinness by creating a fuller mouthfeel. The bubbles stimulate your palate, making flavours pop. Force carbonation gives you precise control, which is critical for hitting the same profile batch after batch.

Low-Sugar Is Your Competitive Advantage

The kombucha brands capturing mainstream retail space aren't just making fermented tea. They're solving the sugar problem whilst delivering taste that converts casual buyers into repeat customers.

Getting there requires methodical work on fermentation protocols, sweetener selection, and acidity management. It takes testing and refinement. But the payoff is access to retail channels, consumer segments, and price points that traditional high-sugar kombucha can't reach.

The market is moving in this direction. Retailers are demanding it. Consumers are seeking it. Brands who crack the formulation challenge first capture disproportionate shelf space and customer loyalty.

For brands planning to scale through co-packing, understanding how to optimise recipes for co-packing whilst maintaining low-sugar targets becomes critical. Your co-packer needs clear specs and processes that translate reliably to their equipment.

Download our Kombucha Troubleshooting Guide and learn advanced formulation strategies for commercial-scale production.

Frequently Asked Questions

-

The key is balancing extended fermentation (which consumes sugar but increases acidity) with post-fermentation sweetener additions and acidity management. Ferment to very low residual sugar (under 5g/L), then add non-fermentable sweeteners like erythritol, stevia, or monk fruit. Consider buffering harsh acidity with small amounts of calcium salts or blending in softer organic acids to round out tartness.

-

No single "best" option exists. Erythritol provides clean sweetness with good mouthfeel but has a cooling sensation. Stevia is cost-effective and potent but can taste metallic. Monk fruit delivers clean taste but costs more. Most successful formulations blend 2-3 sweeteners (e.g., erythritol + stevia at 10:1 ratio) to minimise individual off-notes whilst maximising sweetness perception.

-

No. SCOBY cultures require fermentable sugars (glucose, fructose, sucrose) to function. Non-fermentable sweeteners don't feed the microbes, so fermentation won't occur. You must ferment with traditional sugar, then replace residual sweetness post-fermentation with alternatives, or use pre-fermented bases that were originally fermented with sugar but now contain none.

-

It depends on production method. If you ferment traditionally and add sweeteners post-fermentation without pasteurising, live cultures remain active (though slower due to reduced sugar). If you pasteurise for shelf stability, probiotics are killed (some brands re-add specific strains). If using pre-fermented bases, the base itself contains organic acids and fermented compounds but typically not live cultures unless specifically added back.

-

Lower initial sugar means lower potential alcohol production during fermentation. Extended fermentation allows bacteria more time to metabolise alcohol into acetic acid. The combination typically results in lower final alcohol levels (often 0.1-0.3% ABV compared to 0.3-0.5% in traditional kombucha), making regulatory compliance easier. This is one of the hidden advantages of low-sugar formulation for commercial producers.

-

Most UK and EU retailers prefer beverages under 5g sugar per 100ml to avoid high-sugar product restrictions and appeal to health-conscious consumers. For kombucha, that translates to roughly 12-13g sugar per 250ml serving maximum. Brands successfully competing in mainstream channels (Tesco, Sainsbury's, Waitrose) typically hit 2-4g per 100ml, positioning themselves alongside enhanced waters and low-sugar soft drinks rather than traditional kombucha or fruit juice.

-

Usually, yes. Alternative sweeteners like stevia, monk fruit, and erythritol cost more per kilogram than cane sugar. Extended fermentation ties up tank capacity longer, reducing throughput. Fruit purées and natural flavourings needed to compensate for sugar reduction add ingredient costs. However, extended shelf life, reduced cold chain requirements (if using shelf-stable bases), and premium retail pricing often justify higher production costs. The economics depend heavily on your specific formulation and go-to-market strategy.